serving hattiesburg and the surrounding area.

(columbia, petal, purvis, sumrall, laurel, USM, jcjc, jones county, lamar county, forrest county)

this is a solder repair here in hattiesburg of fender’s first ever in-ear monitors – the FXA7.

i help with worship at venture church, and one of my fellow pdub musicians (pdub is church musician lingo for praise and worship – p for praise and dub is for the W in worship) had recently retired his rather expensive pair of fender in-ear monitors. he had purchased a new custom set and allowed a fellow singer to use these older ones .

they had developed a rattle and were cutting in and out. he mentioned them to me and i told him to let me open them up to see what was going on inside. maybe i could help revive them as they were the top of the line for the range that fender was offering them for $100-$500. would be great to have a fresh set of $500 in-ear monitors on hand as a back up or to resell.

now the design of this pair is a 3-D printed generic design in-ear monitor – meaning that this model with fit most people and feels like a custom molded design, but not actually a true custom molded monitor (which can be much more expensive). this design also uses a single dynamic driver with no balanced armature drivers included.

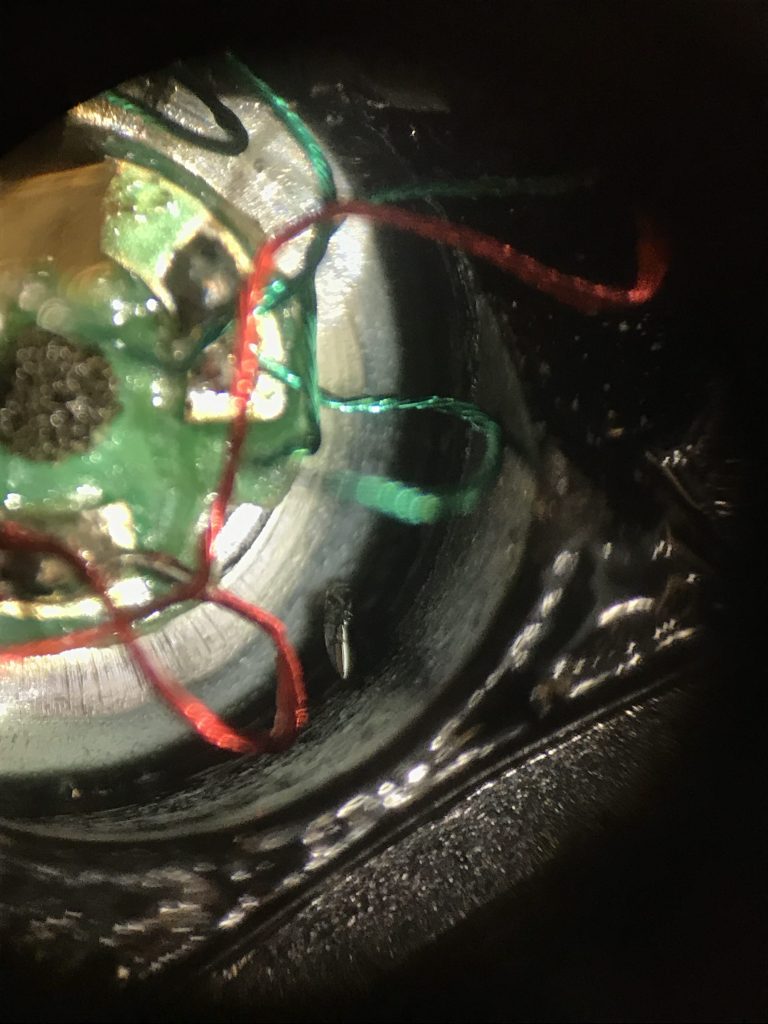

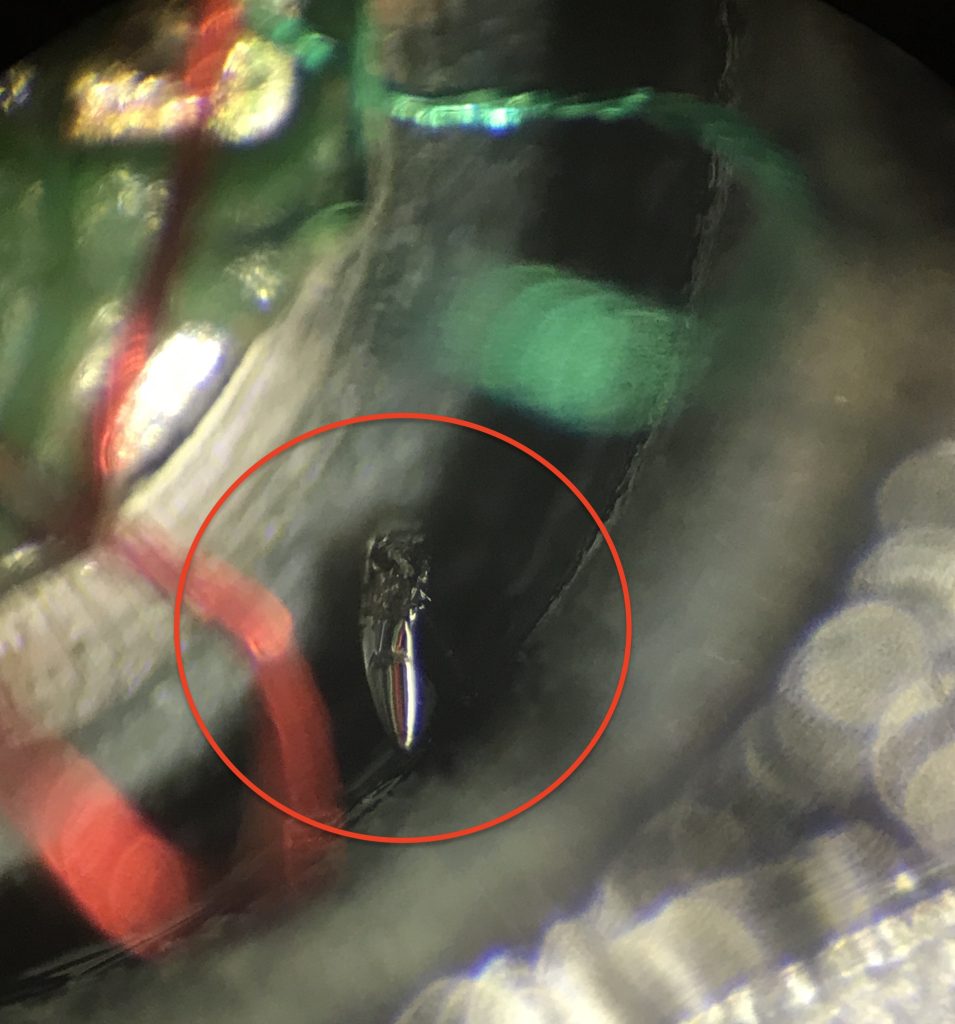

when i first opened them up i saw a problem in one side almost immediately. i wonder if you can see it.

a small chunk of solder was floating around inside the cavity – and i imagine, at times, vibrating up against the dynamic driver used in this design. also noticed the wires were also against the driver as well.

it was loose and just floating around inside. so removed that and plugged them in to see if the problem had been taken care of. we still had a cutting in and out on the other side. so closed this one up and focused on the next problem.

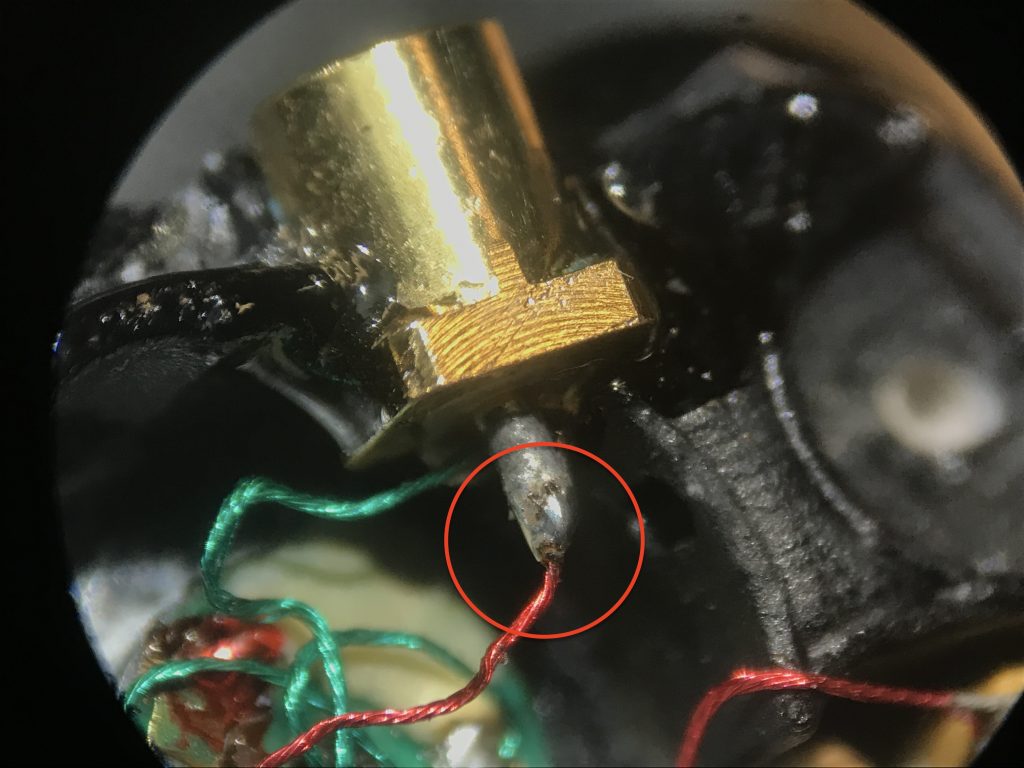

i noticed that the female MMCX connectors were kind of just floating around, and the cutting in and out happened when the connector was moved. so the first thing to do was reseat the connectors and seal them properly again. i used a nice clear resin i’ve had great success with. see below. this was the good side.

i then moved over to the other side and when i pulled the connector out to apply some resin beneath it, the hot wire (red), just slid out from beneath the solder. the magnet wire was broken, but still held lightly in place with the clump of solder (i didn’t get a before picture) and when i moved the connector, it let go. was just enough of a connection to work, but when the cable connected to the female connector was moved, it would cut out. that must have been quite frustrating. musicians rarely stand still. at least most that i’ve worked with. this was a fortunate discovery as not so apparent damage can be sometimes difficult to uncover. diagnosis is a large part of the repair process. once the problem is discovered, it’s not usually difficult to move on to the repair portion of the fix.

i melted the coating back on the magnet wire to get a clean end and resoldered it back and then sealed the connector back in place with the resin.

i finished by sealing them back up and performing some tests. and all is fixed. mr. fxr can now mark these as fixed!

[…] i have been helping at a church that only uses in ear monitors. as a bass player, these tiny in ear speakers severely limit the bass experience i have been used to. bass players are used to “pushing […]

[…] i have been helping at a church that only uses in ear monitors. as a bass player, these tiny in ear speakers severely limit the bass experience i have been used to. bass players are used to “pushing […]